The 17th edition of China’s SoG Silicon and PV Power Conference has been held in Suzhou. As the country’s most important academic conference in the field of silicon materials and PV power, the event has closely followed cutting-edge PV technology and the latest application topics, earning an enviable reputation and global influence. Dr. Lyu Jun, President of LONGi’s product management centre, delivered a keynote speech at the conference entitled “Technical Development of Crystalline Silicon Solar Cells and Modules Driven by ‘Double Carbon’ Goals”.

Focus on solar cell innovation to allow competition in PV to be based on advanced technology

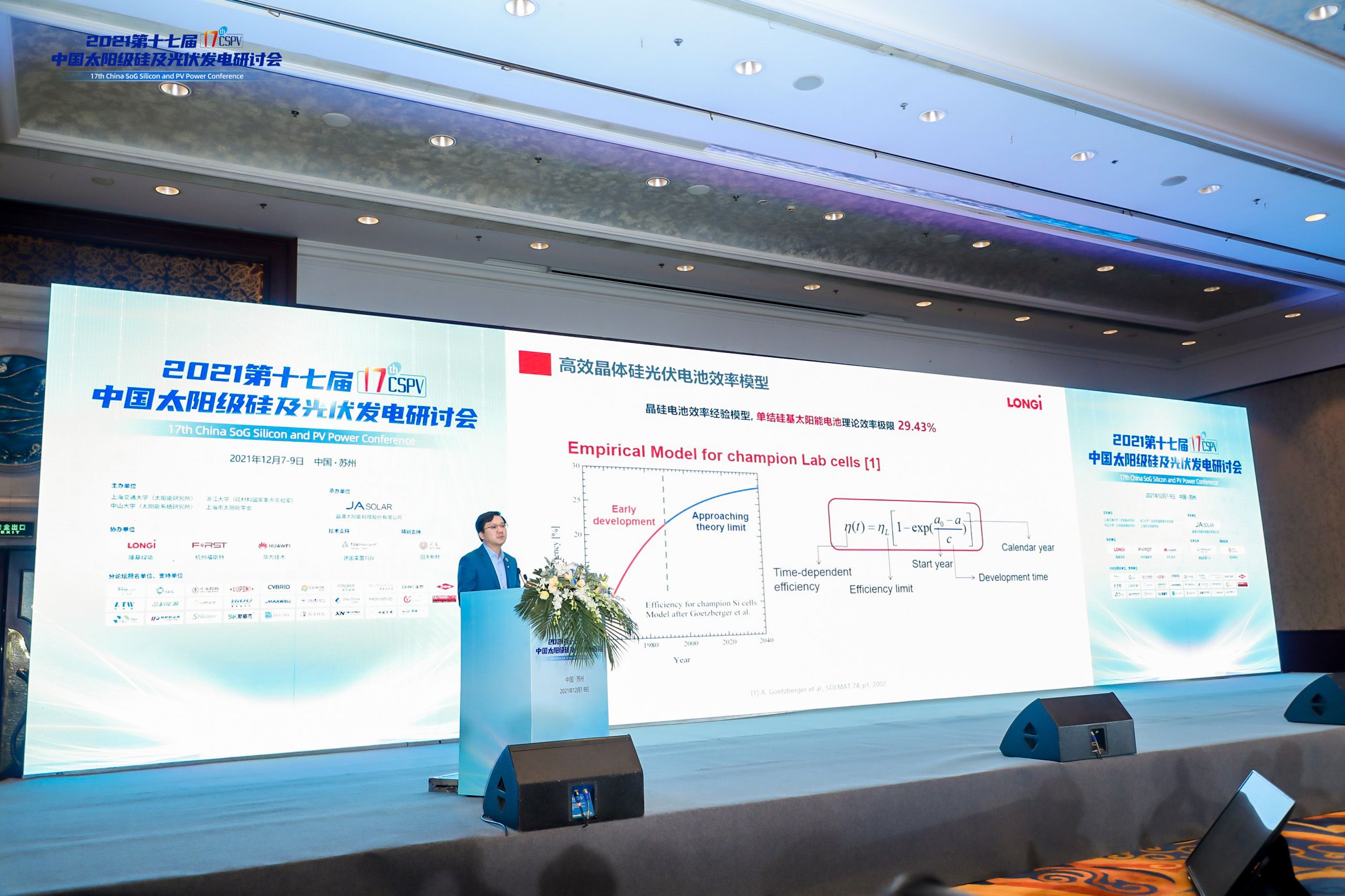

In his address, Dr. Lyu stated that, since the turn of the century, the crystalline silicon cell industry has developed rapidly. According to the empirical model of cell efficiency, the theoretical limit for single-junction silicon-based solar cells is 29.43%. The current industrialized high-efficiency solar cells are mainly: P-type PERC, N-type TOPCon and HJT, with PERC continuing to be mainstream technology for the next three years. Going forward, with increasing market competition, further improving the mass production efficiency of PERC cells and accelerating the elimination of outdated production capacity in favour of advanced production capacity will be the main objective.

Looking at the future industry trend for high-efficiency cells, Dr. Lyu believes that passivation contact technology is the main development direction (TOPCon and HJT), with multi-junction cell stacking technology still under continuous research.

According to the Institut für Solarenergieforschung in Hameln (ISFH), the theoretical efficiency limits for PERC, HJT and TOPCon cells are 24.5%, 28.5% and 28.7% respectively. LONGi has already set a high benchmark for technological innovation in each of these high-efficiency cell types, continually refreshing its own world records – indeed, in terms of HJT technology, the company has established new world records three times in the past six months.

In May of this year, LONGi officially released a white paper on the unique crackless technology behind the Hi-MO 5 module, in the form of its proprietary “Smart Soldering.”

Dr. Lyu went on to explain that, with the development of module technology, in order to reduce internal current and resistance, series-parallel design after slicing has now become the mainstream solution. The integrated segmented soldering strip used in LONGi’s Smart Soldering technology has a yield strength 12.9% lower than that of a conventional soldering strip, reducing lamination cracking, with the integrated molding and annealing process further enhancing fatigue resistance to ensure long-term reliability.

Improving reliability and economy of PV products to create sustainable value for customers

Continuing on the theme of the development of module technology, Dr. Lyu suggested that, as cell efficiency becomes higher and module size larger, product power continues to increase and reliability risks are also potentially increasing. As a product that will be used for 25 years and possibly more, a PV module can bring sustainable value to global customers only on the premise of reliability.

“The glass performance in larger modules is impacted by the influence of the process, with frame stress increasing, the margin of junction box diodes decreasing, and the packaging method during transportation making it difficult to ensure the reliability of the modules.” Dr. Lyu believes that, based on the double glass structure and under the premise of controlling the cost of the frame, module size should not exceed a certain limit, otherwise the ability to withstand static and dynamic loads will be significantly compromised, increasing the potential for frame damage, glass bursts and higher quantities of cracks leading to excessive module attenuation under laboratory testing and outdoor application conditions.

LONGi’s approach is to consider LCOE as the foundation for product value, incorporating economy and reliability. “LONGi Lifecycle Quality” standard establishes a system that is in line with a real world outdoor environment, effectively evaluating the outdoor risks for modules, maximizing customer value based on product reliability.

Dr. Lyu pointed out that LONGi based its Hi-MO 5 module solution on the best LCOE, in-depth analysis of the value of the whole industrial chain and the boundary constraints in regard to the increasing size of modules. Without improving efficiency, continuing to increase module size to achieve higher power will no longer reduce system costs, and could bring a significant increase in reliability risk. A standardized module size would be conducive to the focus of all links in the PV industry chain, including manufacturing equipment, auxiliary materials, inverters and trackers, allowing for a return to the basic priority of technological innovation.